ZLTECH Nema23 57mm 24V 35W/70W/100W/140W 3000RPM DC brushless motor for engraving machine

A BLDC motor with three coils on the stator will have six electrical wires (two to each coil) extending from these coils. In most implementations three of these wires will be connected internally, with the three remaining wires extending from the motor body (in contrast to the two wires extending from the brushed motor described earlier). Wiring in the BLDC motor case is more complicated than simply connecting the power cell’s positive and negative terminals.

The advantages of BLDC motor:

1. Efficiency. As these motors can control continuously at maximum rotational force (torque). Brushed motors, in contrast, reach maximum torque at only certain points in the rotation. For a brushed motor to deliver the same torque as a brushless model, it would need to use larger magnets. This is why even small BLDC motors can deliver considerable power.

2. Controllability. BLDC motors can be controlled, using feedback mechanisms, to delivery precisely the desired torque and rotation speed. Precision control in turn reduces energy consumption and heat generation, and—in cases where motors are battery powered—lengthens the battery life.

3. BLDC motors also offer high durability and low electric noise generation, thanks to the lack of brushes. With brushed motors, the brushes and commutator wear down as a result of continuous moving contact, and also produce sparks where contact is made. Electrical noise, in particular, is the result of the strong sparks that tend to occur at the areas where the brushes pass over the gaps in the commutator. This is why BLDC motors are often considered preferable in applications where it is important to avoid electrical noise.

We’ve seen that BLDC motors offer high efficiency and controllability, and that they have a long operating life. So what are they good for? Because of their efficiency and longevity, they are widely used in devices that run continuously. They have long been used in washing machines, air conditioners, and other consumer electronics; and more recently, they are appearing in fans, where their high efficiency has contributed to a significant reduction in power consumption.

Parameters

| Item | ZL57DBL35 | ZL57DBL70 | ZL57DBL100 | ZL57DBL150 |

| Phase | 3 Phase | 3 Phase | 3 Phase | 3 Phase |

| Size | Nema23 | Nema23 | Nema23 | Nema23 |

| Voltage (V) | 24 | 24 | 24 | 24 |

| Rated Power (W) | 35 | 70 | 100 | 140 |

| Rated Current (A) | 2.1 | 4.2 | 6 | 8.4 |

| Peak Current (A) | 6.3 | 12.6 | 18 | 25 |

| Rated Torque (N.m) | 0.11 | 0.22 | 0.33 | 0.45 |

| Peak Torque (N.m) | 0.33 | 0.66 | 1 | 1.35 |

| Rated Speed (RPM) | 3000 | 3000 | 3000 | 3000 |

| No. of Poles (Pairs) | 2 | 2 | 2 | 2 |

| Resistance (Ω) | 1.5±10% | |||

| Inductance (mH) | 4.2±20% | |||

| Ke (RMS)(V/RPM) | 3.4x10-3 | 3.4x10-3 | 3.4x10-3 | 3.4x10-3 |

| Rotor Inertia (kg.cm²) | 0.054 | 0.119 | 0.172 | 0.23 |

| Torque Coefficient (N.m/A) | 0.018 | 0.018 | 0.018 | 0.11 |

| Shaft Diameter (mm) | 8 | 8 | 8 | 8 |

| Shaft Length (mm) | 21 | 21 | 21 | 21 |

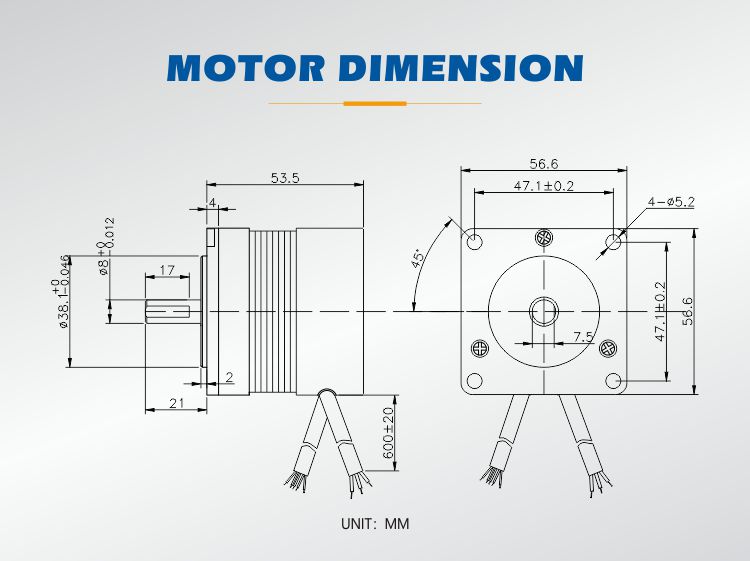

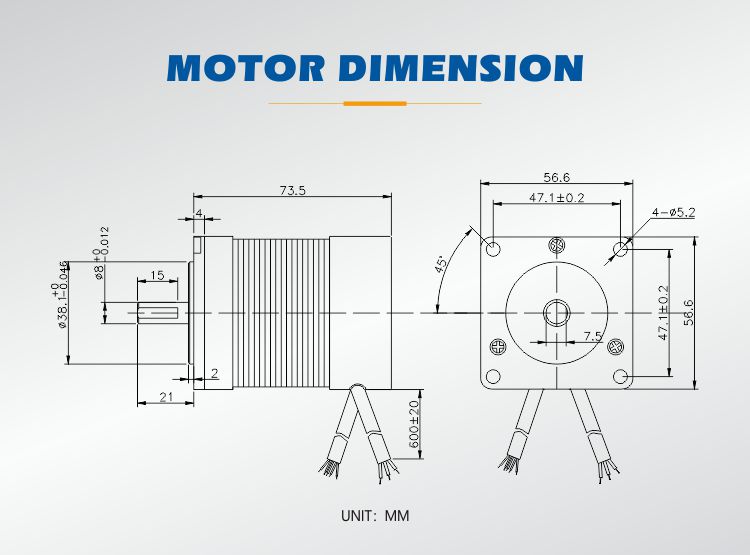

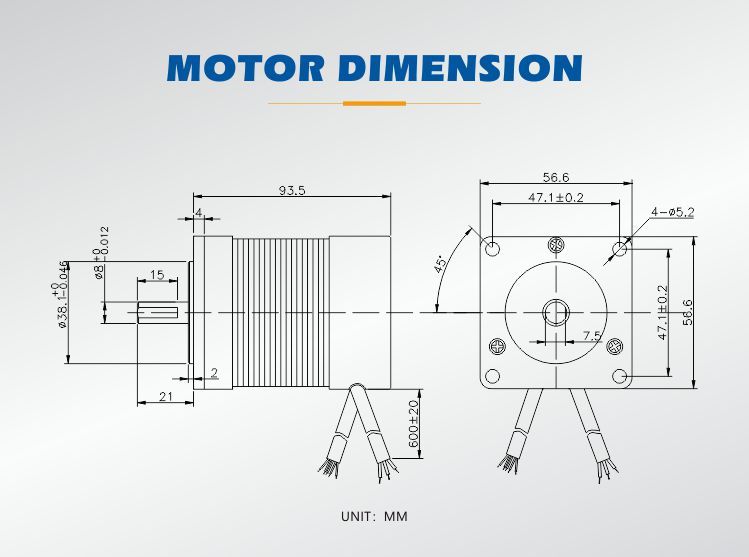

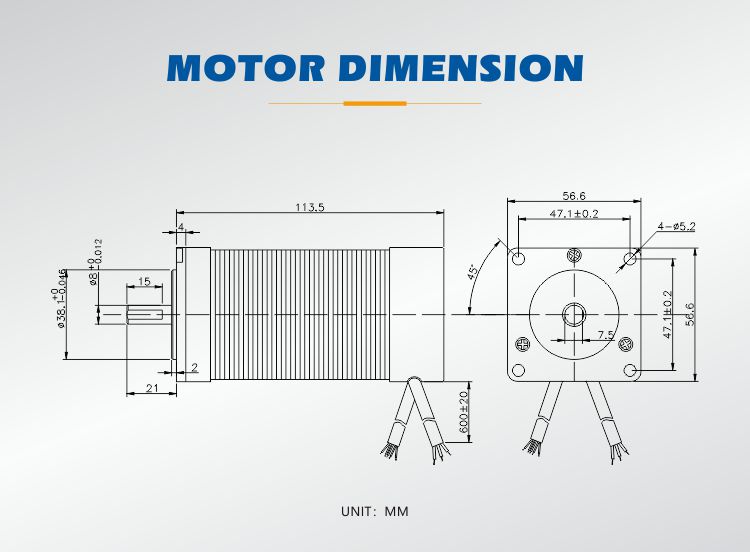

| Motor Length (mm) | 53.5 | 73.5 | 93.5 | 113.5 |

| Weight (kg) | 0.5 | 0.75 | 1 | 1.25 |

| Adapted BLDC Driver | ZLDBL4005S | ZLDBL4005S | ZLDBL5010S | ZLDBL5010S |

Dimension

Application

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation