ZLTECH 3phase 60mm Nema24 24V 100W/200W/300W/400W 3000RPM BLDC motor for printing machine

A Brushless DC Electric Motor (BLDC) is an electric motor powered by a direct current voltage supply and commutated electronically instead of by brushes like in conventional DC motors. BLDC motors are more popular than the conventional DC motors nowadays, but the development of these type of motors has only been possible since the 1960s when semiconductor electronics were developed.

Similarities BLDC and DC motors

Both types of motors consist of a stator with permanent magnets or electromagnetic coils on the outside and a rotor with coil windings that can be powered by direct current on the inside. When the motor is powered by direct current, a magnetic field will be created within the stator, either attracting or repelling the magnets in the rotor. This causes the rotor to start spinning.

A commutator is needed to keep the rotor rotating, because the rotor would stop when it is in line with the magnetic forces in the stator. The commutator continuously switches the DC current through the windings, and thus switches the magnetic field too. This way, the rotor can keep rotating as long as the motor is powered.

Differences BLDC and DC motors

The most prominent difference between a BLDC motor and a conventional DC motor is the type of commutator. A DC motor uses carbon brushes for this purpose. A disadvantage of these brushes is that they wear quickly. That is why BLDC motors use sensors – usually Hall sensors – to measure the position of the rotor and a circuit board that functions as a switch. The input measurements of the sensors are processed by the circuit board which it accurately times the right moment to commutate as the rotor turns.

Parameters

| Item | ZL60DBL100 | ZL60DBL200 | ZL60DBL300 | ZL60DBL400 |

| Phase | 3 Phase | 3 Phase | 3 Phase | 3 Phase |

| Size | Nema24 | Nema24 | Nema24 | Nema24 |

| Voltage (V) | 24 | 24 | 48 | 48 |

| Rated Power (W) | 100 | 200 | 300 | 400 |

| Rated Current (A) | 5.5 | 11.5 | 8.3 | 12 |

| Peak Current (A) | 16.5 | 34.5 | 25 | 36 |

| Rated Torque (N.m) | 0.32 | 0.63 | 0.96 | 1.28 |

| Peak Torque (N.m) | 1 | 1.9 | 3 | 3.84 |

| Rated Speed (RPM) | 3000 | 3000 | 3000 | 3000 |

| No. of Poles (Pairs) | 4 | 4 | 4 | 4 |

| Resistance (Ω) | 0.22±10% | 0.59±10% | 0.24±10% | |

| Inductance (mH) | 0.29±20% | 0.73±20% | 0.35±20% | |

| Ke (RMS)(V/RPM) | 4.2x10-3 | 4.2x10-3 | 8.3x10-3 | 8.5x10-3 |

| Rotor Inertia (kg.cm²) | 0.24 | 0.48 | 0.72 | 0.96 |

| Torque Coefficient (N.m/A) | 0.06 | 0.06 | 0.09 | 0.12 |

| Shaft Diameter (mm) | 8 | 8 | 14 | 14 |

| Shaft Length (mm) | 31 | 30 | 31 | 31 |

| Motor Length (mm) | 78 | 100 | 120 | 142 |

| Weight (kg) | 0.85 | 1.25 | 1.5 | 2.05 |

| Adapted BLDC Driver | ZLDBL5010S | ZLDBL5015 | ZLDBL5010S | ZLDBL5015 |

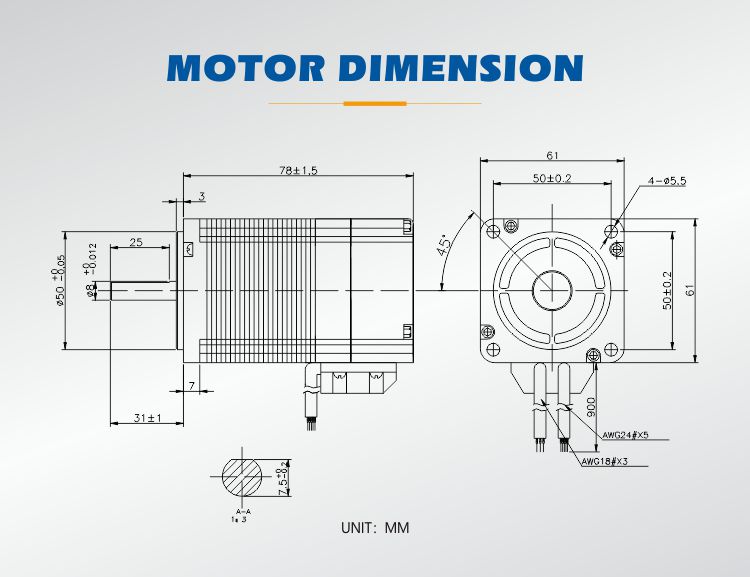

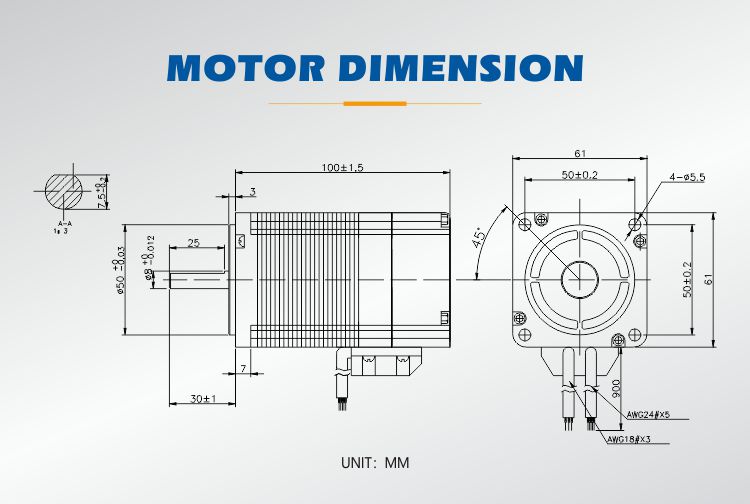

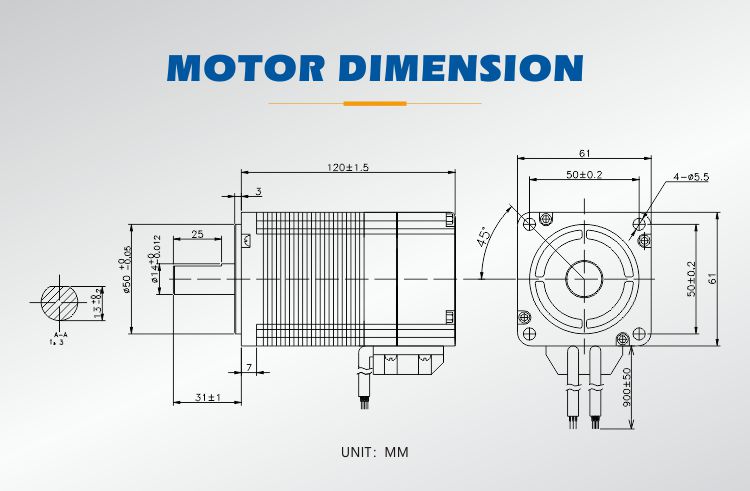

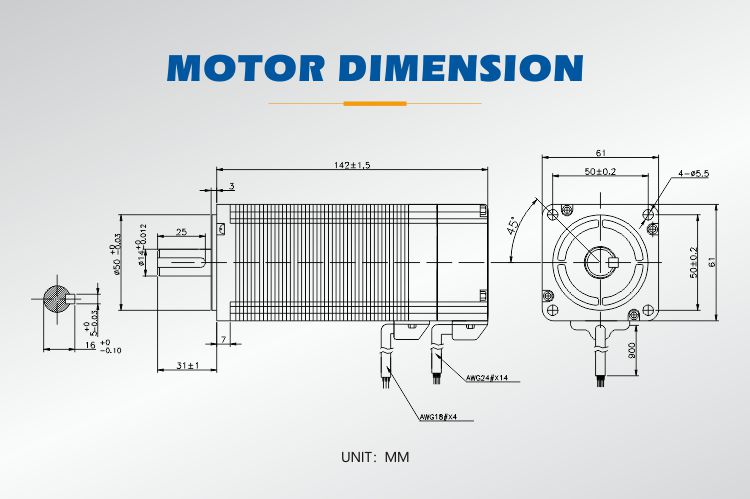

Dimension

Application

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation