Short Lead Time for 36v Wheelchair Bldc Hub Motor - ZLTECH 86mm Nema34 24-50VDC 3000RPM BLDC motor for engraving machine – ZhongLing

Short Lead Time for 36v Wheelchair Bldc Hub Motor - ZLTECH 86mm Nema34 24-50VDC 3000RPM BLDC motor for engraving machine – ZhongLing Detail:

Characteristics of brushless motor

1) The motor is small in size and lighter in weight. For asynchronous motor, its rotor is composed of iron core with teeth and grooves, and the grooves are used to place induction windings to generate current and torque. The outer diameter of all rotors should not be too small. At the same time, the existence of mechanical commutator also limits the reduction of the outside diameter, and the armature winding of brushless motor is on the stator, so the outside diameter of the rotor can be relatively reduced.

2) The motor loss is small, this is because the brush is cancelled, and the electronic reversing is used to replace the mechanical reversing, so the friction loss and electric loss of the motor are eliminated. At the same time, there is no magnetic winding on the rotor, so the electric loss is eliminated, and the magnetic field will not produce iron consumption on the rotor.

3) The motor heating is small, this is because the motor loss is small, and the armature winding of the motor is on the stator, directly connected to the casing, so the heat dissipation condition is good, the heat conduction coefficient is large.

4) High efficiency. Although brushless motor is widely used and has a large power range, the application efficiency of different products is also different. In fan products, the efficiency can be improved by 20-30%.

5) the speed regulation performance is good, for the brushless motor through the potentiometer to adjust the voltage to achieve stepless or gear speed regulation, as well as PWM duty cycle speed regulation and pulse frequency speed regulation.

6) Low noise, small interference, low energy consumption, large starting torque, no mechanical friction caused by reversing.

7) High reliability, long service life, eliminating the need of brushes to eliminate the source of main motor faults, electronic commutator motor heating is reduced, motor life is extended.

Parameters

| Item | ZL86DBL500-36V | ZL86DBL500-48V | ZL86DBL750 |

| Phase | 3 Phase | 3 Phase | 3 Phase |

| Size | Nema34 | Nema34 | Nema34 |

| Voltage (V) | 36 | 48 | 48 |

| Rated Power (W) | 500 | 500 | 750 |

| Rated Current (A) | 19 | 14 | 17 |

| Peak Current (A) | 57 | 42 | 51 |

| Rated Torque (N.m) | 1.6 | 1.6 | 2.4 |

| Peak Torque (N.m) | 4.8 | 4.8 | 7.2 |

| Rated Speed (RPM) | 3000 | 3000 | 3000 |

| No. of Poles (Pairs) | 4 | 4 | 4 |

| Resistance (Ω) | 0.15±10% | 0.30±10% | 0.10±10% |

| Inductance (mH) | 0.30±20% | 0.60±20% | 0.30±20% |

| Ke (RMS)(V/RPM) | 6.2×10-3 | 8.5×10-3 | 8.5×10-3 |

| Rotor Inertia (kg.cm²) | 0.42 | 0.42 | 2.4 |

| Torque Coefficient (N.m/A) | 0.09 | 0.115 | 0.115 |

| Shaft Diameter (mm) | 14 | 14 | 14 |

| Shaft Length (mm) | 32 | 32 | 32 |

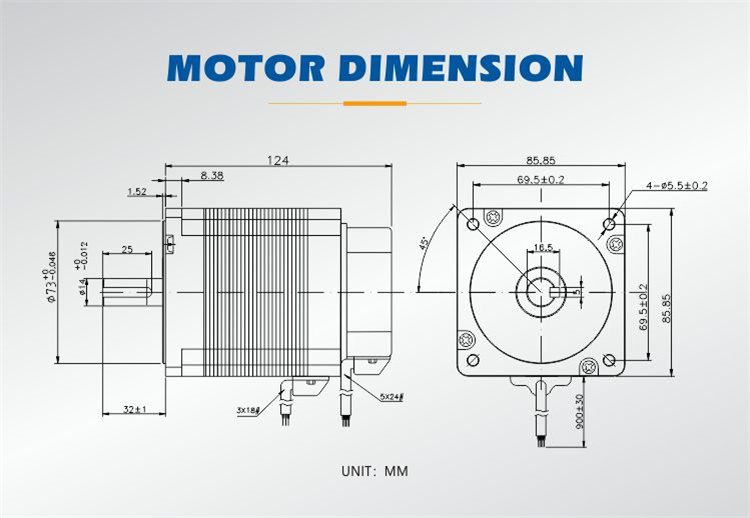

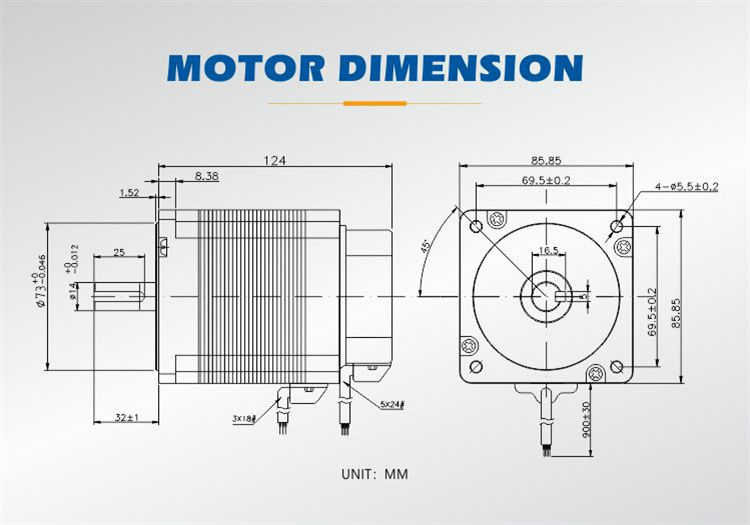

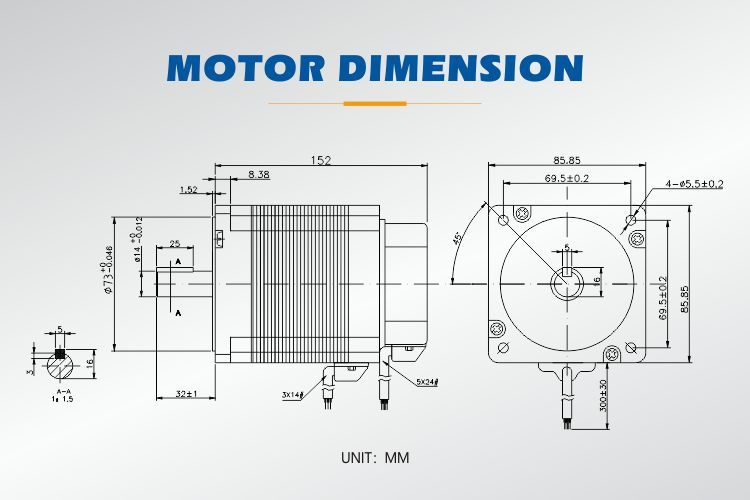

| Motor Length (mm) | 124 | 124 | 152 |

| Weight (kg) | 2.6 | 2.6 | 4 |

| Adapted BLDC Driver | ZLDBL5030S | ZLDBL5015 | ZLDBL5030S |

Dimension

Application

Brushless DC motors are widely used in electronic manufacturing, medical equipment, packaging equipment, logistics equipment, industrial robots, photovoltaic equipment and other automation fields.

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Short Lead Time for 36v Wheelchair Bldc Hub Motor - ZLTECH 86mm Nema34 24-50VDC 3000RPM BLDC motor for engraving machine – ZhongLing , The product will supply to all over the world, such as: Kuala Lumpur, Albania, Cologne, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.