Geared motor it refers to the integration of a reducer and a motor. This type of integrated body is commonly referred to as a geared motor. Usually, after being integrated and assembled by a professional gearbox manufacturer, it is supplied as a complete set together with the motor. A reduction motor is a power transmission mechanism that is used in applications that require high torque and do not require too high speed. For example, conveyor belts, mixers, winches, clappers, and specialized automation machines, and with the development of industry and the automation of factories, the demand for their use of reducers is increasing day by day.

There are many methods for reducing speed, but the most commonly used method is to use gears to reduce speed, which can reduce the occupied space and lower costs. Therefore, some people also refer to reducers as gearboxes. A reducer is a relatively precise mechanical device used to reduce speed and increase torque. It has a wide variety of types, different models, and different types have different purposes. There are many types of reducers: according to the transmission type, they can be divided into gear reducers, worm gear reducers, and planetary gear reducers; According to different transmission stages, it can be divided into single-stage and multi-stage reducers; According to the shape of gears, they can be divided into cylindrical gear reducers, bevel gear reducers, and cone cylindrical gear reducers; According to the arrangement of transmission, it can be divided into expansion type, diversion type, and coaxial type reducers.

Today we will analyze the differences between several common reducers.

1. Steering box

Steering box, also known as commutator or steering gear, is a type of power transmission mechanism and a series of reducers, which has a wide range of applications in the industrial field. The steering box has single axis, double horizontal axis, single vertical axis, and double vertical axis options. Speed ratios of 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, and 5:1 are all actual transmission ratios. The steering box can operate in both forward and reverse directions, with smooth low-speed or high-speed transmission. When the speed ratio of the steering box is not 1:1, the horizontal axis input and vertical axis output are deceleration, and the vertical axis input and horizontal axis output are acceleration.

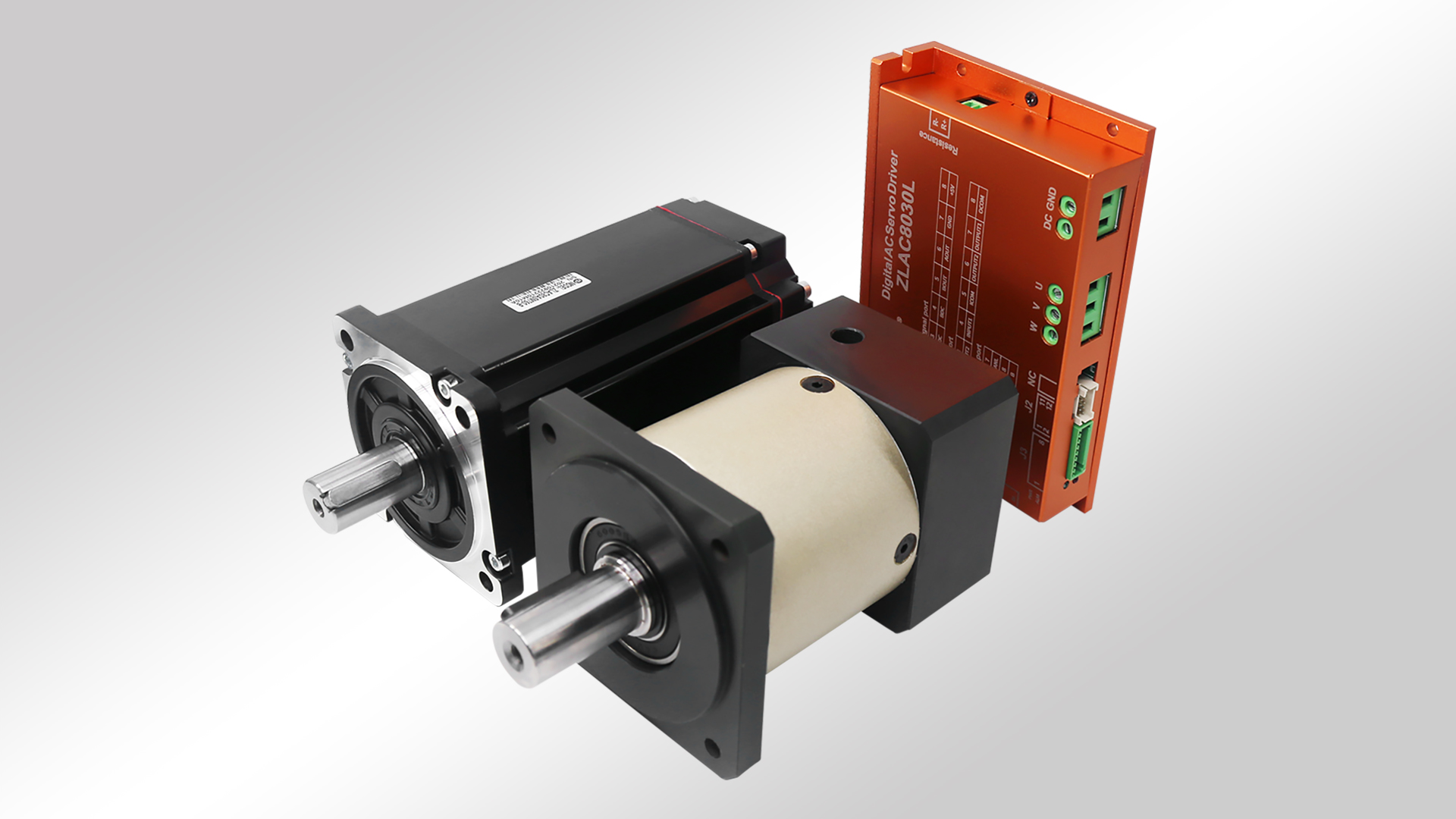

2 planetary gearbox

In the reducer family, planetary reducers are widely used in servo, stepper, DC and other transmission systems due to their small size, high transmission efficiency, wide reduction range, and high precision. Its function is mainly used to reduce speed, increase torque, and reduce the load/motor moment of inertia ratio while ensuring precision transmission. When the concentricity between the motor and the reducer is ensured very well during assembly, the output shaft of the motor only bears the rotational force and runs smoothly. However, when they are not concentric, the output shaft has to bear radial forces from the input end of the reducer. The long-term effect of this radial force will force the motor output shaft to bend, and the direction of bending will constantly change with the rotation of the output shaft. The direction of lateral force changes 360 degrees for every rotation of the output shaft. If the concentricity error is large, the radial force will cause the temperature of the motor output shaft to rise, and its metal structure will be continuously damaged. This radial force will exceed the radial force that the motor output shaft can withstand, leading to the breakage of the drive motor output shaft. The larger the concentricity error, the shorter the time it takes for the output shaft of the drive motor to break. At the same time as the output shaft of the driving motor breaks, the input end of the reducer will also bear radial forces from the motor. If this radial force exceeds the maximum radial load that both can bear, the result will also cause deformation or even fracture of the input end of the reducer. Therefore, it is important to maintain concentricity during assembly.

In general, the development of reliability and stability of deceleration motors is mainly reflected through the advantages of improving transmission efficiency, precise control, reducing load fluctuations, increasing transmission accuracy and load capacity. These advantages have led to the widespread application of reduction motors in various industrial fields and mechanical equipment. As an important mechanical transmission device, the reduction motor has a wide range of application fields and unique advantages. In various applications such as industrial automation, robotics, medical equipment, aerospace, logistics and transportation, deceleration motors can be used to achieve precise motion control and position adjustment, ensuring the normal operation and reliability of equipment. Shenzhen Zhongling Technology Co., Ltd. has been dedicated to the research and development, production, and sales of industrial automation control products since its establishment in 2013.

Post time: Mar-26-2025