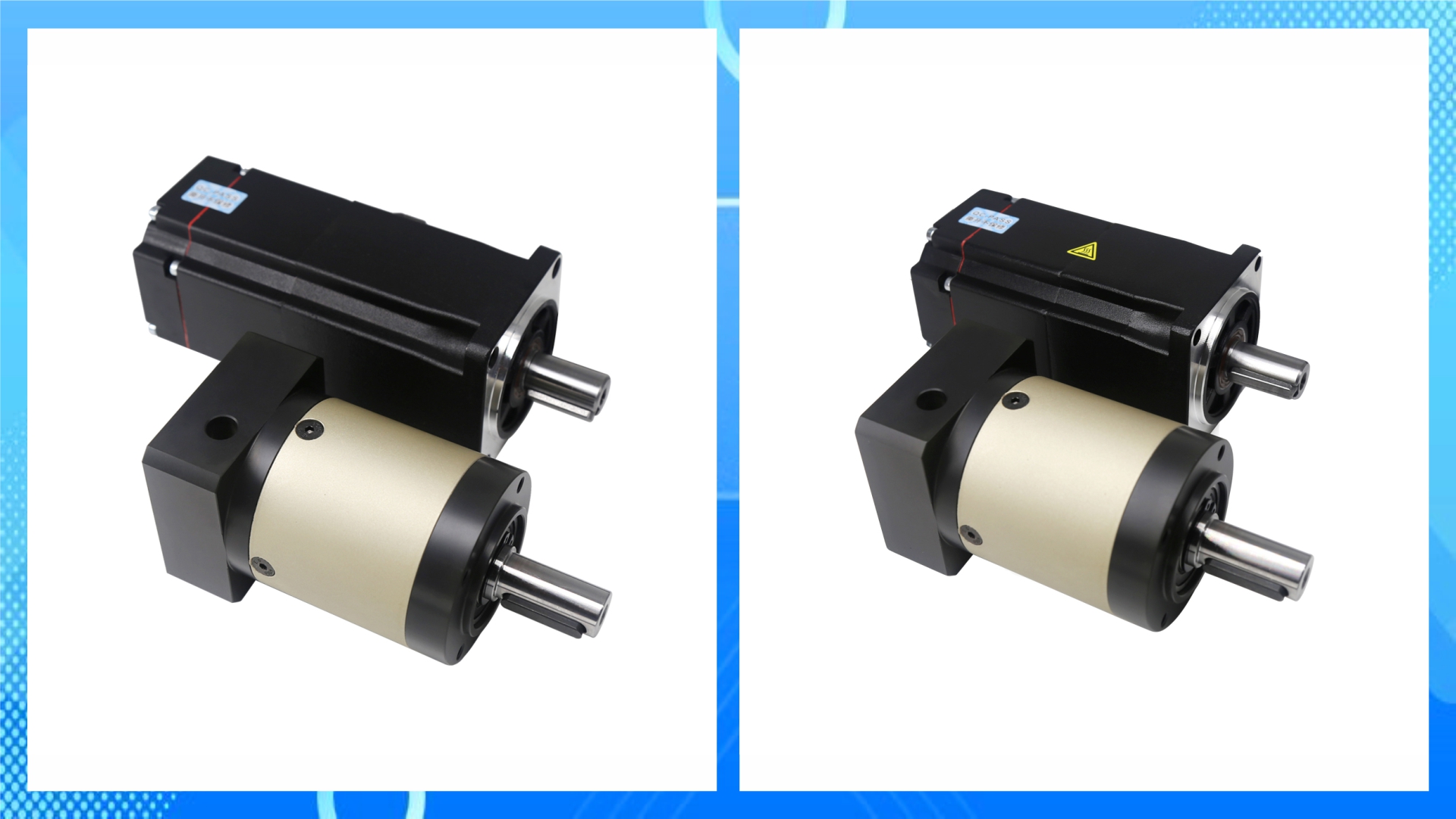

Geared motor is an important mechanical transmission device that combines motor and gearbox, and has many unique applications and advantages. This article will provide a detailed introduction to the usage and application areas of deceleration motors.

1.The usage of the geared motor

1)Adjust speed

Geared motor could reduce the output speed of motor to meet specific work requirements. For example, in certain situations where precise speed control is required, such as production lines, mechanical equipment, medical devices, etc., geared motor could be used to achieve precise speed control.

2) Increase torque

Geared motor could also increase torque by reducing speed. Although high-speed motors can provide greater power, in certain situations that require high torque, such as lifting heavy objects, driving large mechanical equipment, etc., it is necessary to use geared motor to increase torque and ensure the normal operation of the equipment.

3) Convert energy

Geared motor could convert electrical energy into mechanical energy, thereby driving mechanical equipment to operate. In various applications that require the conversion of electrical energy into mechanical energy, such as industrial automation, robotics, aerospace, etc., geared motor could be used as power sources.

2.Application field of geared motor

1) Automation

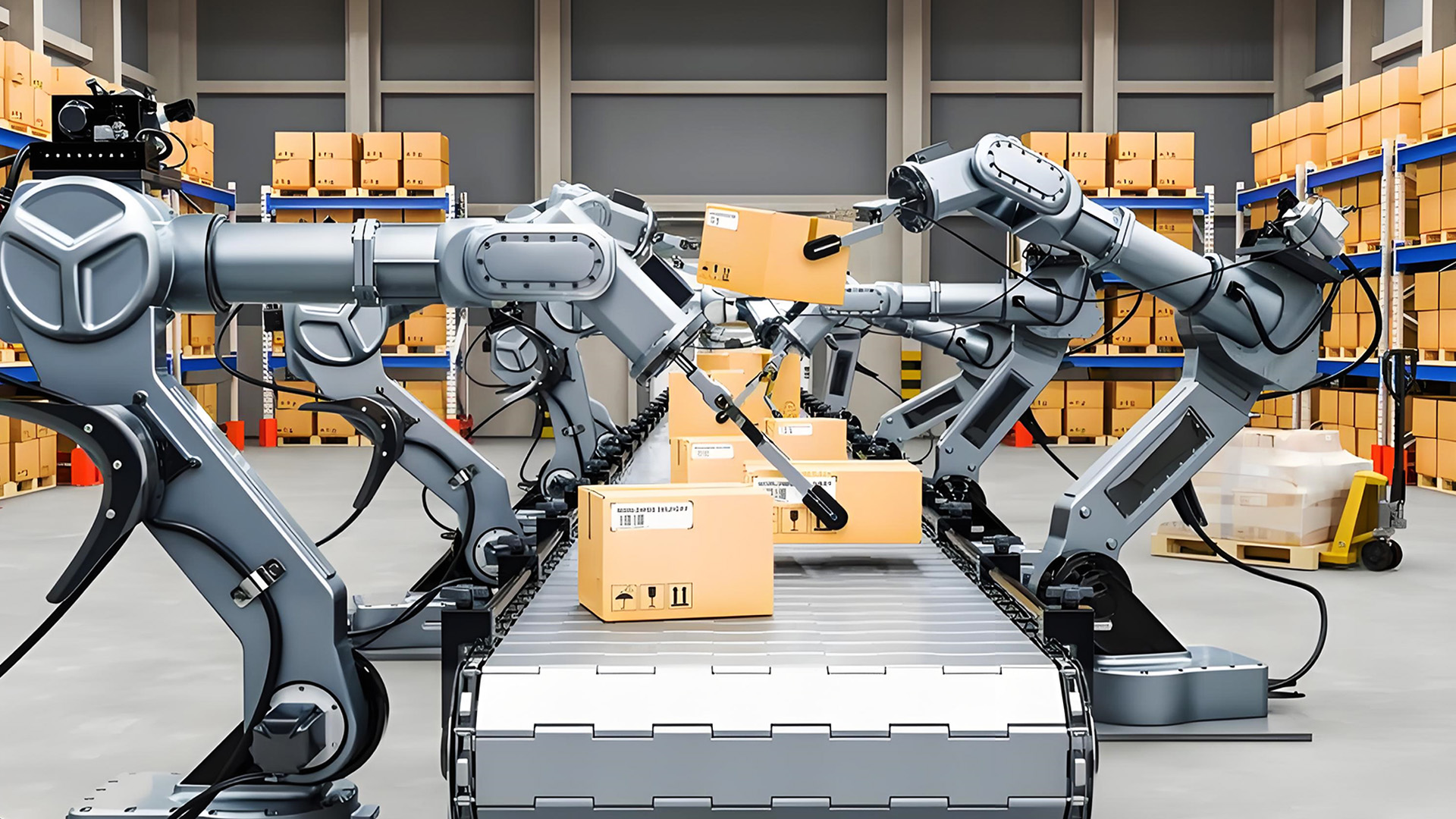

In the field of industrial automation, geared motor is widely used in various mechanical equipment. For example, in the production line, conveyor belts, robotic arms, material handling and other links, geared motor could be used to drive the operation of mechanical equipment. In addition, in heavy machinery such as injection molding machines and presses, geared motor is also required to provide sufficient torque and precise speed control

2) Robot

Robot is one of the important application areas of geared motor. On robot, geared motor is typically used to drive servo systems, joints, and arm movements. Due to the high flexibility and precision required for robots, the use of geared motor could ensure its movement is more precise, stable, and reliable.

3) Medical equipment

In the field of medical equipment, geared motor is also widely used in various devices. For example, in surgical robots, medical imaging equipment, treatment equipment, etc., geared motor is required to achieve precise motion control and position adjustment. In addition, geared motor could also be used to drive the operation of equipment such as cleaning and disinfection machines in medical device cleaning and disinfection processes.

4) Aerospace

In the aerospace field, geared motor is also widely used in various equipment. For example, in aircraft such as airplanes and rockets, geared motor is needed to drive the operation of servos, pumps, and other mechanical equipment. In addition, in satellites and other space probes, geared motor is also required to drive the movement of equipment such as robotic arms and solar panels.

5) Logistics transportation

In the field of logistics transportation, geared motor is also widely used in various equipment. For example, in automated warehouses and logistics sorting systems, it is necessary to use geared motor to drive conveyor belts, elevators, and other mechanical equipment to operate. In addition, in logistics equipment such as electric forklifts and handling vehicles, geared motor is also required to provide sufficient torque and precise speed control.

The development of geared motor in terms of reliability and stability mainly reflects the following advantages:

1.High efficiency performance: geared motor reduces the output speed of the motor through a deceleration device, while increasing the output torque, thereby improving the transmission efficiency and system efficiency.

2.Precise control: geared motor could achieve precise control of output speed and torque by adjusting the reduction ratio, adapting to different working conditions and application requirements, and improving the control performance of the system.

3.Reduce load fluctuations: deceleration device could balance the fluctuations of the load, reduce the impact on the motor and system due to load changes, and improve the stability and reliability of the system.

4.Increase transmission accuracy: geared motor improves transmission accuracy through a reduction device, reducing transmission errors and return errors, and is suitable for situations where high transmission accuracy is required.

5.Increase load capacity: geared motor increases the output torque through the deceleration device, enhancing the system’s adaptability to loads and enabling it to withstand larger loads and impact loads.

In general, the development of reliability and stability of geared motor is mainly reflected through the advantages of improving transmission efficiency, precise control, reducing load fluctuations, increasing transmission accuracy and load capacity. These advantages have led to the widespread application of geared motors in various industrial fields and mechanical equipment. As an important mechanical transmission device, geared motor has a wide range of application fields and unique advantages. In various applications such as industrial automation, robotics, medical equipment, aerospace, logistics and transportation, geared motor can be used to achieve precise motion control and position adjustment, ensuring the normal operation and reliability of equipment.

Shenzhen Zhongling Technology Co., Ltd. has been dedicated to the research and development, production, and sales of industrial automation control products since its establishment in 2013. Dedicated to the research of various motors.

Post time: Jul-22-2024