The hub motor aging test and inspection standards can be specified by the customer. If there are no special requirements, the aging test and inspection will be carried out according to the corresponding national standards. The aging test is mainly a high-intensity test that simulates various harsh conditions of the product during actual use, and at the same time, reasonably predicts the service life of the product based on the requirements of use.

The purpose of aging testing is to achieve a satisfactory pass rate. Almost all products must undergo aging before leaving the factory. The first reason for aging is to improve product reliability, and so far there is no other alternative. For new products, the performance of new components or complete machines must be assessed, and the aging index will be higher. Aging exposes product defects before leaving the factory, such as the reliability of welding points, and various defects in product design, materials and processes; aging causes product performance to enter a stable range before leaving the factory, reducing the repair rate.

Electrical and automotive products, whether they are components, parts, complete machines, or equipment, must be aged and tested. Aging and testing are not the same concept. Aging first and then testing. After electronic products (all products are like this) are manufactured, they form The complete product can already exert its use value, but after using it, it is found that there are some problems, and it is found that most of these problems occur within a few hours to dozens of hours. Later, the electric vehicle products are simply stipulated. Aging and testing, imitating the usage status of or equivalent products, this process is completed by the product manufacturer. Through re-testing, problematic products are kept in the factory, and non-problematic products are given to users to ensure that the products bought to users are Reliable or less problematic. This is the meaning of burn-in testing.

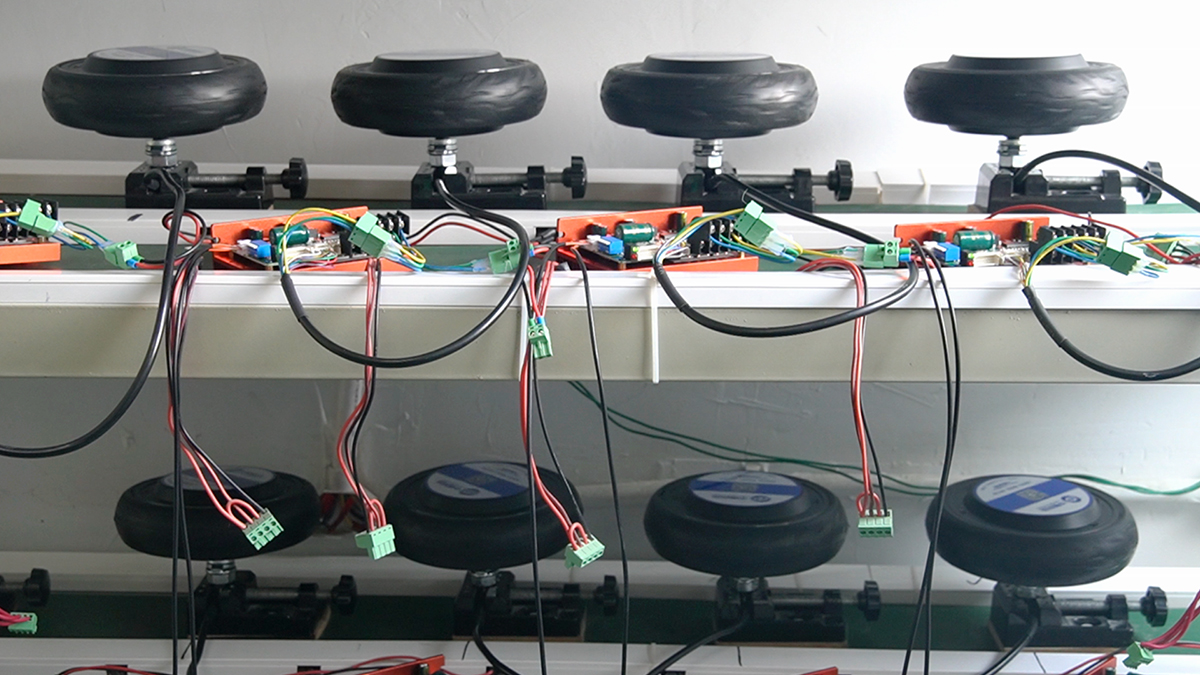

Shenzhen Zhongling Technology’s robot hub motors will pass a 24-48 hour aging test to ensure product quality. With the promotion of the concept of “artificial intelligence”, Zhongling Technology’s wheel hub motors have been widely used in unmanned distribution, unmanned cleaning, auxiliary medical and other industries. Shenzhen Zhongling Technology will also continue to optimize product design and production processes, constantly improve product materials and performance, and inject power into the robot industry!

Post time: Sep-20-2024