In the rapidly developing field of robotics technology today, the performance and customization level of wheel hub motors, as the core driving components, directly affect the motion ability and application scenarios of robots. The customization of robot wheel hub motors is not only related to the optimization of technical parameters, but also a deep exploration of the overall performance and adaptability of robots. This article will delve into the customization direction of robot wheel hub motors, especially brake customization, shaft customization, tire customization, and end cap customization, revealing how to create more efficient and reliable robot motion control systems through refined customization strategies.

1.Brake customization: precise stopping and starting, safe and worry free

In the customization of robot wheel hub motors, the customization of the braking system is the key to ensuring the stable operation of the robot. Unlike traditional vehicle braking systems, the braking of robot wheel hub motors requires fast response, high-precision control, and long lifespan. The customized braking system can adjust key parameters such as braking torque and response time according to the specific application scenario of the robot, achieving smooth stopping and precise positioning of the robot. In addition, the use of advanced electromagnetic braking or intelligent braking technology can further enhance the precision and safety of robot motion control.

2.Shaft customization: carrying the core, rotating the future

As the core component of wheel hub motors, the degree of customization of the shaft directly affects the output torque, speed, and service life of the motor. In the shaft customization of robot wheel hub motors, it is necessary to comprehensively consider factors such as the robot’s load requirements, motion speed, and working environment. By optimizing the material, structure, and processing technology of the shaft, the bearing capacity and transmission efficiency of the motor can be significantly improved. For example, using high-strength alloy materials can effectively improve the bending strength and wear resistance of the shaft; And precision machining technology can ensure smooth rotation of the shaft, reducing vibration and noise during the motion process.

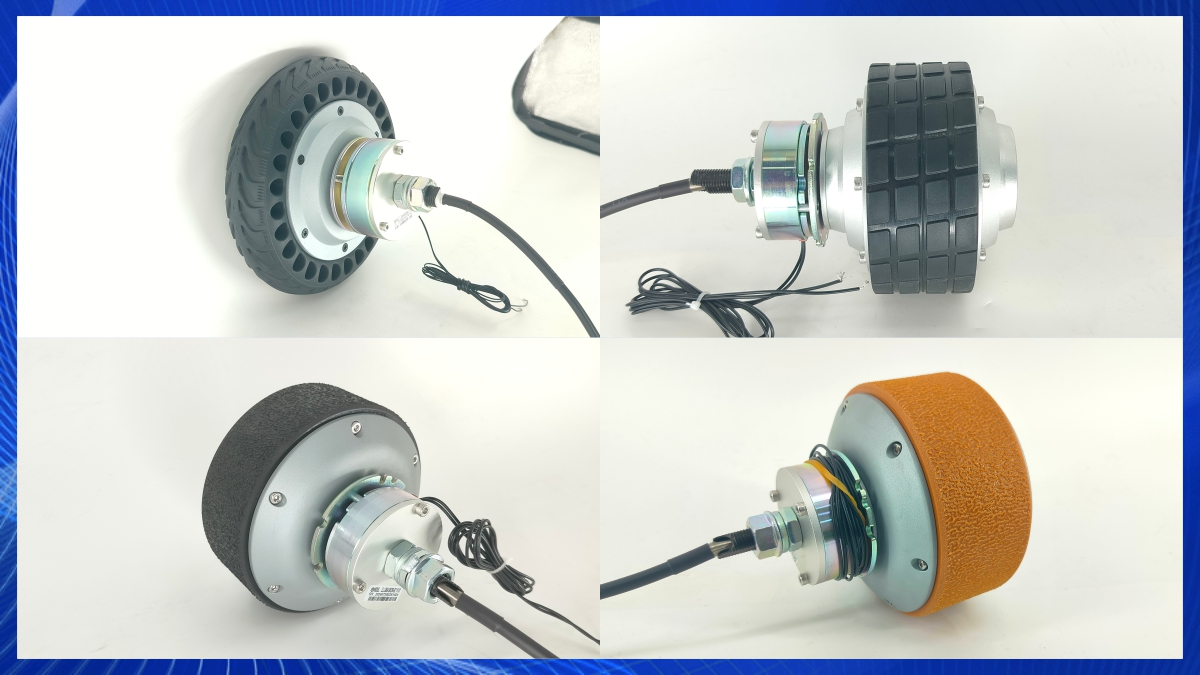

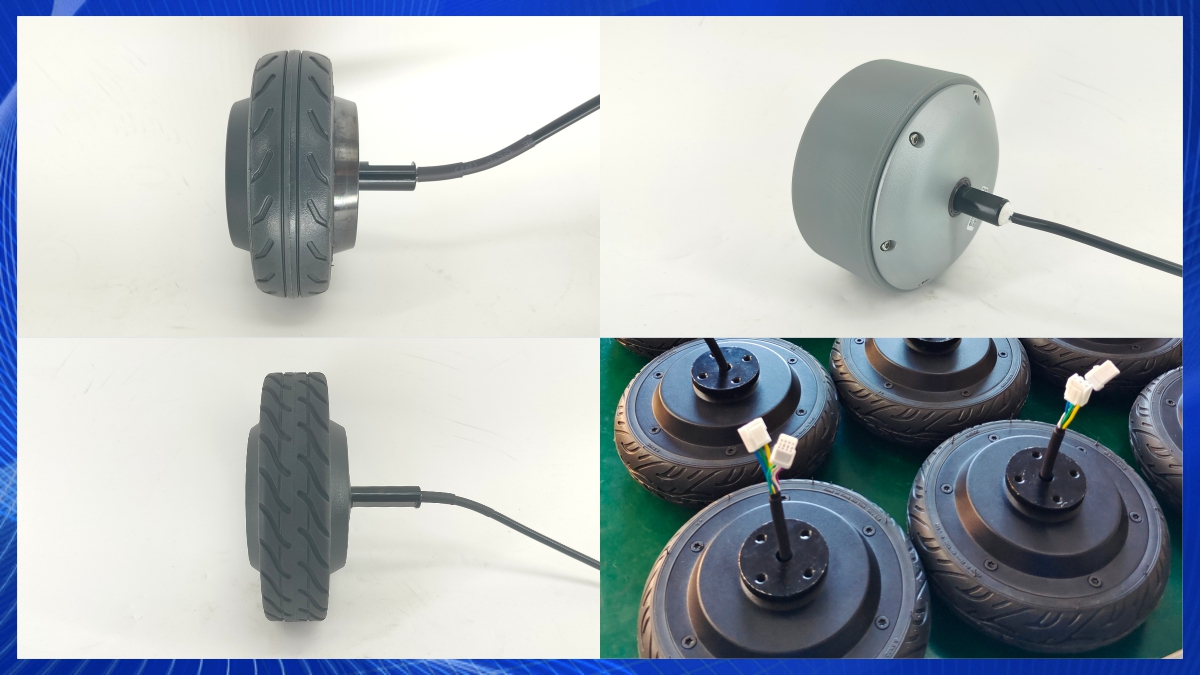

3.Tire customization: adaptable to diversity, walking without boundaries

As the direct contact point between robots and the ground, the degree of customization of tires has a crucial impact on the robot’s motion performance and environmental adaptability. In the customization of tires for robot wheel hub motors, it is necessary to choose the appropriate tire material, pattern, and size according to the application scenario of the robot. For example, robots operating in uneven or complex terrain can choose rubber tires with good elasticity and wear resistance, and be equipped with special pattern designs to enhance the robot’s grip and passability. Through customized tire design, robots can also achieve low-noise motion or efficient walking in special environments.

4.Cover customization: For details, please refer to the official seal

As a protective component for wheel hub motors, the end cap may seem simple, but it contains many details during the customization process. Customized end cap design not only enhances the overall aesthetics of the motor, but also effectively protects the precision components inside the motor from external environmental erosion. In the customization of end caps, it is necessary to comprehensively consider factors such as the motor’s heat dissipation requirements, protection level, and installation convenience. For example, using advanced heat dissipation materials and technologies can ensure stable heat dissipation of the motor under high-intensity operation; The rigorous protective design can effectively prevent impurities such as dust and moisture from entering the interior of the motor, extending its service life.

In summary, the customization direction of robot wheel hub motors is a complex project involving multiple disciplines and fields. By implementing refined strategies such as brake customization, axle customization, tire customization, and end cap customization, the motion performance, environmental adaptability, and service life of robots can be significantly improved. For beginners, a deep understanding of these customized directions not only helps to better grasp the technical essence of robot wheel hub motors, but also provides strong technical support and innovative ideas for subsequent robot design and application. In the future development of robot technology, customized robot wheel hub motors will become an important force in promoting a new chapter of efficient motion control.

When choosing a customized motor, it is recommended to have in-depth communication with a professional motor manufacturer to ensure that the selected solution can meet your specific needs. Through customized solutions, you will be able to stand out in fierce market competition and drive your robot project forward. Shenzhen Zhongling Technology has been focusing on the robot wheel hub motor industry for many years, integrating research and development, production, and sales.

Post time: Oct-22-2024