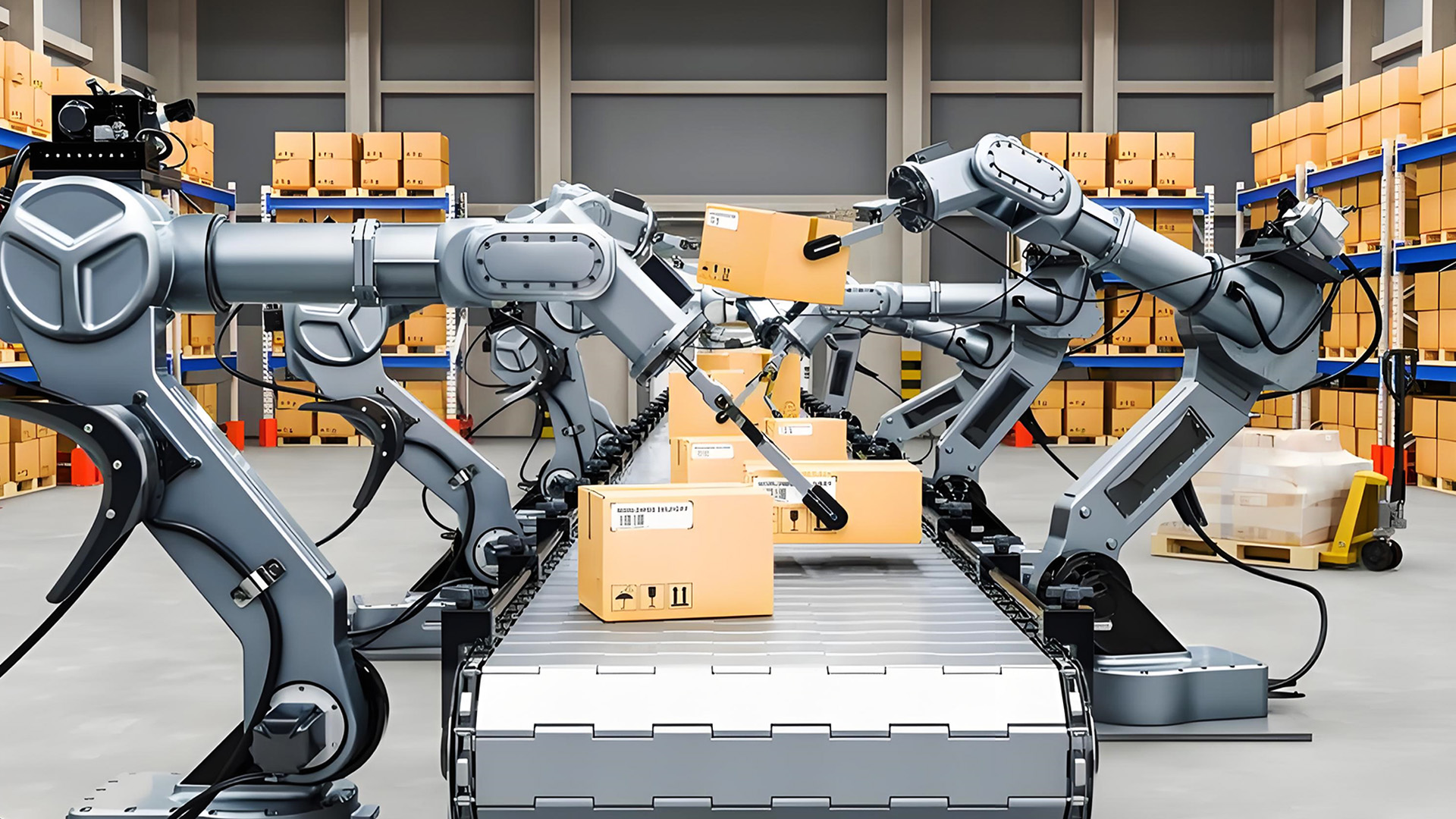

As the focus of the industrial field, servo motors are widely used in 3C industrial robots and automation. In recent years, servo system products have entered the industrialization stage. The servo system is an automatic control system that enables the output controlled quantities such as the position, orientation, and state of an object to follow any changes in the input target (or given value). Among them, the servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. The application scope of servo motors is such equipment as machine tools, printing equipment, automated production lines, etc. that have relatively high requirements for process accuracy, processing efficiency, and work reliability.

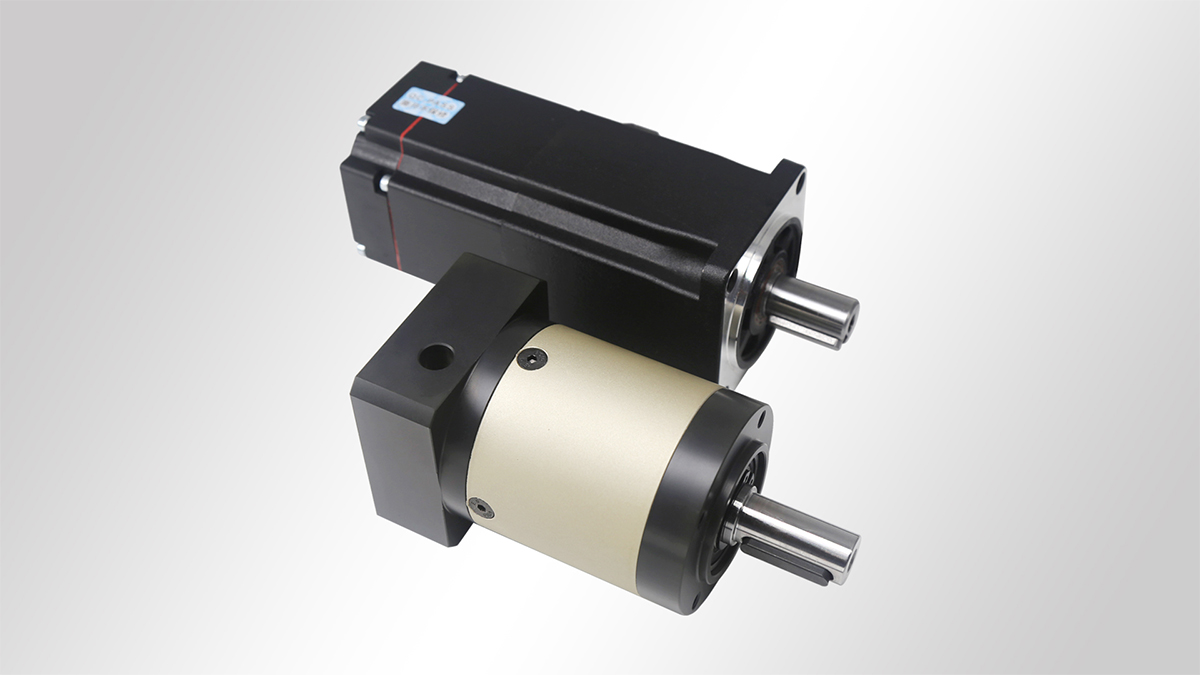

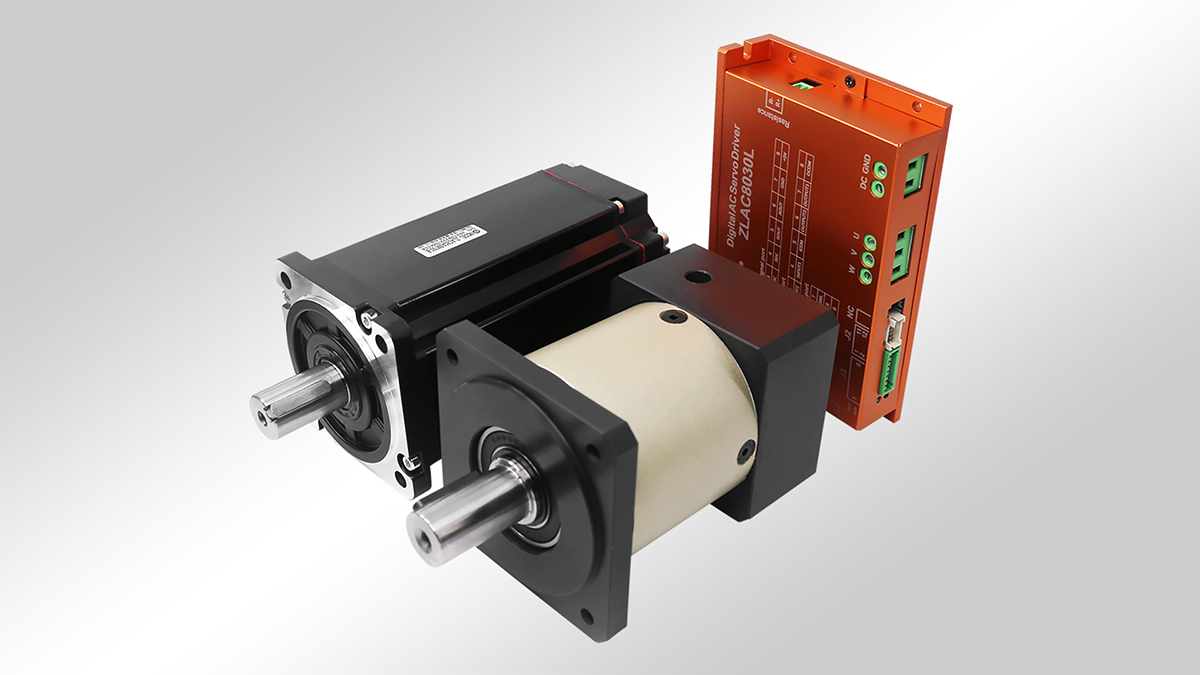

Shenzhen Zhongling Technology Co., Ltd. has launched high-torque, high-precision precision planetary reducers to meet various applications. With the development of servo motor technology, modern industrial equipment is being used more and more widely, from high torque density to high power density, which increases the speed to more than 3000rpm. Due to the increase in speed, the power density of the servo motor is greatly improved. So the question is, what are the application occasions of servo motor planetary reducers? What are the benefits of such a combination?

The following are occasions where servo motors need to be equipped with reducers:

1. When there is a demand for heavy load and high precision: For example, in the fields of aviation, satellites, medical treatment, military technology, wafer equipment, robots and other automation equipment, the torque required by these devices often far exceeds the torque capacity of the servo motor itself, so a reducer is needed to increase the output torque of the servo motor.

2. When the torque of the equipment needs to be increased: If the equipment adopts the method of directly increasing the output torque of the servo motor, it must use expensive high-power servo motors and high-power drivers, which is too expensive, so it is more appropriate to use a reducer.

3. When the performance of the equipment needs to be improved: When the load inertia of the equipment is not properly matched, the servo control will be unstable. Therefore, for large load inertia, it is generally more appropriate to use the characteristics of the reducer to control.

4. When the cost of equipment needs to be reduced: Using a reducer instead of a high-power servo device can greatly save the purchase cost of the equipment, and invest the funds in other places without affecting the operation of the equipment, so a reducer can be used when the cost of equipment needs to be reduced.

To sum up, whether a servo motor needs to be equipped with a reducer mainly depends on the needs and costs of the equipment application.

Shenzhen Zhongling Technology Co., Ltd. relies on more than ten years of professional experience in motion control design and R&D to provide excellent solutions for enterprises across the country. The main products are hub motors, DC servos, stepper servos, integrated stepper drive systems, DC motors, stepper motors, planetary reducers, reduction motors, servo drive wheels, omnidirectional wheels, etc. If you want to buy our products, please contact our sales staff.

Post time: Nov-15-2024