With the development of the logistics industry, the role of warehouse robots is becoming more and more important. They can automatically perform operations such as the transfer and handling of goods by accepting instructions or pre-set procedures in the system, which greatly improves the operational efficiency and accuracy of the warehouse. As an important drive component, the hub motor plays a key role in the design and operation of the warehouse robot.

First, hub motor technology

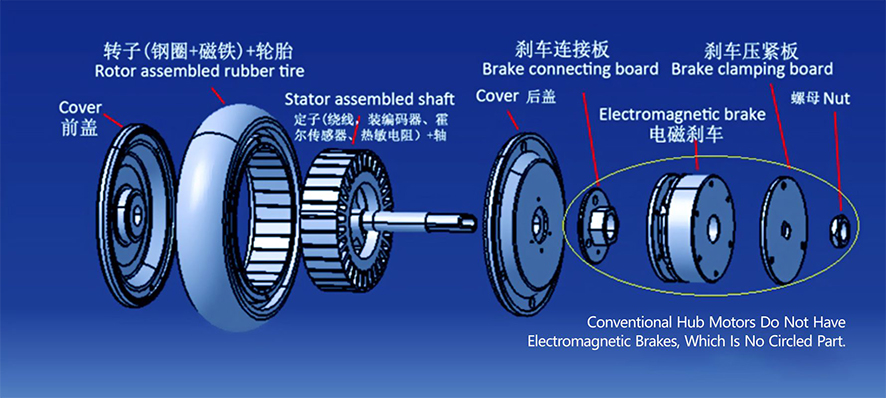

Hub motor, also known as brushless outer rotor hub motor, is the core actuator of robot movement, with fast response speed, small moment of inertia, large overload torque, small torque fluctuation, high efficiency and low-speed stability. Its characteristics are mainly composed of stator, rotor and additional parts, unlike the inner rotor motor, the rotor of the hub motor is composed of a large number of strong magnets around the outer circle of the hub, the stator core is generally made of silicon steel sheet with an insulating layer, used to place the stator winding, the stator winding is distributed at the same angle on the center of the circle, that is, each at an angle of 120 degrees, the coil on the winding is wound according to a certain law, and the stator winding flows through the current to generate a rotating magnetic field. At this time, the rotating magnetic field and the rotor conductor have relative cutting motion, according to the principle of electromagnetic induction, the rotor conductor generates induced electromotive force and generates induced current, the rotor conductor is subjected to electromagnetic force in the magnetic field, forming electromagnetic torque, driving the rotor to rotate. In layman’s terms, it is the process of converting the electrical energy of the current into mechanical energy.

Second, storage robots

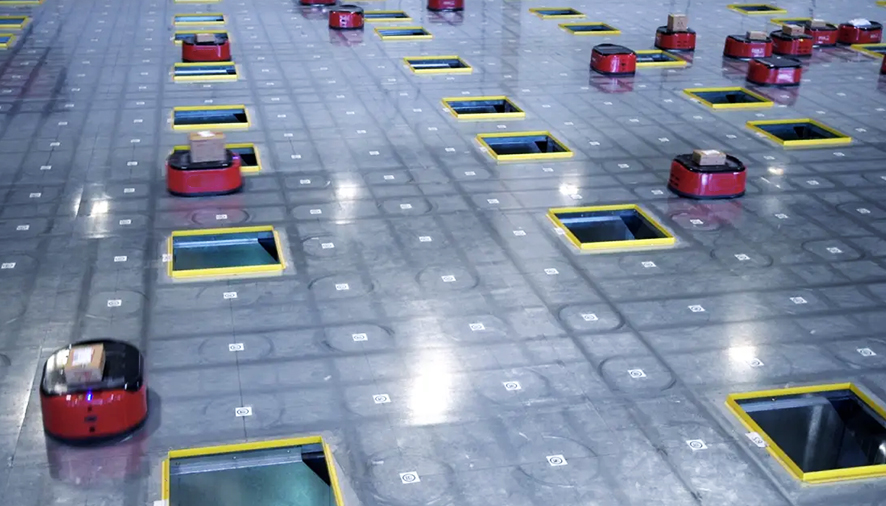

According to the application scenarios, warehouse robots are mainly divided into AGV robots, AMR robots, RGV robots, palletizing robots and sorting robots. AGVs automatically guide trolleys along tracks or predetermined routes to complete automated, repetitive tasks, often requiring manual operator supervision; AMR autonomous mobile robots use cameras, sensors, artificial intelligence, and machine vision to independently navigate an uncontrolled environment to complete a variety of tasks; RGV shuttle truck can run with forklifts, stacker cranes, shuttle mother trucks to achieve automatic three-dimensional warehouse access and fast running speed. Strong flexibility, simple operation, palletizing robots are used to stack goods or perform logistics tasks such as packing and shipping, and the speed and efficiency of heavy objects handling operations are high; Sorting robots can use image recognition systems to distinguish the shape of items. Grab the items with a robot and put them in the designated position to achieve rapid sorting of goods.

In summary, the hub servo motor plays an important role in the storage robot, first of all, the motor and the outer wheel are integrated, easy to disassemble and assemble, low speed and stable, fast response, so that the design and layout of the equipment is more flexible. Secondly, the built-in high-precision encoder provides precise motion control and positioning for the robot, and can accurately navigate and perform operations such as the transfer and handling of goods according to the set path. Efficient and accurate cargo handling is achieved, improving the operational efficiency of the warehouse.

With the development of science and technology, warehouse robots will play an increasingly important role in the logistics industry. As its core drive component, the brushless external rotor hub motor drive will play a key role in the future development. By continuously improving the performance and reducing the cost of in-wheel motors, we can expect warehouse robots to play a greater role in the logistics industry.

Post time: Aug-15-2023