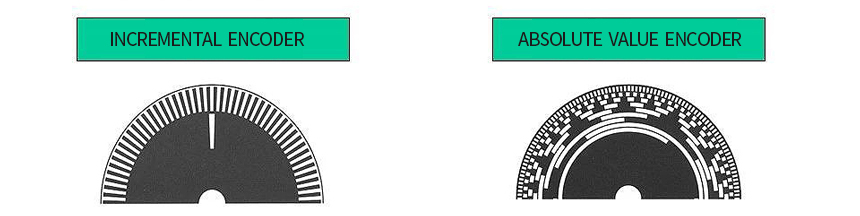

1. Different working methods:

Incremental encoder needs to go back to the origin after power off. It cannot output the absolute position information of shaft rotation. It has zero cumulative error and poor anti-interference. The receiving equipment needs to be powered off and memorized when it is turned off.

The absolute encoder does not need to return to the origin, it is coded by the mechanical position, no memory is required, it needs to find a reference point, and it does not need to count all the time. When you need to know the position, you can read its position.

2. The working principle is different:

There are many optical channel engraving lines on the absolute encoder optical disc, and each engraving line is arranged with 2 lines, 4 lines, 8 lines and 16 lines in turn. In this way, at each position of the encoder, by reading each engraved line Pass and dark, obtain a unique binary code (Gray code) from the zero power of 2 to the n-1 power of 2, which is called an n-bit absolute encoder. Such an encoder is composed of Optical code disk for memory.

Absolute encoders do not have repeated signal output within a specific rotation period range, and the position encoding for each angle is unique. Absolute encoders are divided into single-turn and multi-turn, and the difference between single-turn and multi-turn absolute encoders is only the difference in the output range of the angular position encoding. The range of the former is only one turn, while the latter can do Multi-turn rotational position measurement.

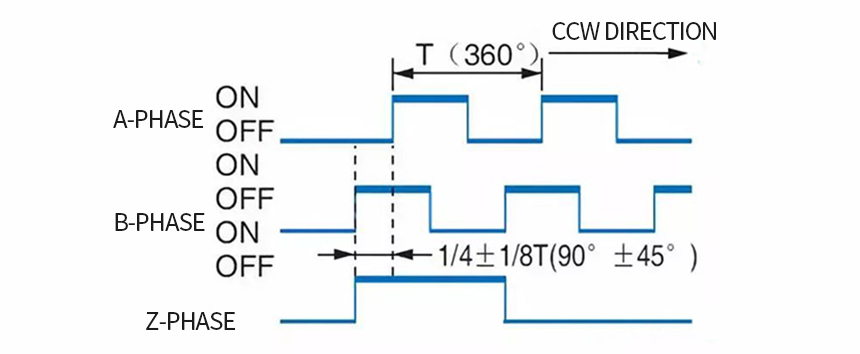

The incremental encoder directly uses the photoelectric conversion principle to output three groups of square wave pulses A, B and Z phases. From a photoelectric code disc with a shaft in the center, on which there are ring-shaped and dark scribe lines, and read by photoelectric transmitting and receiving devices, two sets of sine wave signals are obtained and combined into A and B, each sine wave has a phase difference of 90 degrees. difference (360 degrees relative to one cycle), and output a Z-phase pulse per revolution to represent the zero reference bit.

Since the phase A and B differ by 90 degrees, the forward rotation and reverse rotation of the encoder can be judged by comparing the phase A or phase B before, and the zero reference position of the encoder can be obtained through the zero pulse.

3. Different structure:

Incremental encoder consists of a photoelectric code disc with a shaft in the center, which is read by photoelectric transmitting and receiving devices, and obtains four sets of sine wave signals combined into A, B, C, D, each sine wave has a phase difference of 90 degrees, The C and D signals are reversed and superimposed on the A and B phases to enhance the stable signal; in addition, a Z-phase pulse is output per revolution to represent the zero reference position. There are many optical channel lines on the absolute encoder optical disc.

Shenzhen Zhongling Technology Co., Ltd. has been focusing on the manufacturing and research and development of incremental encoder hub motors since its establishment, and is in a leading position in the industry. The products produced by the company today are exported to major robot companies at home and abroad, and its products have accompanied customers in more than 100 countries around the world. Under the development of the company's own professional and experienced R&D team, the absolute encoder in-wheel motor developed and produced is also widely accepted by customers.

Post time: Jan-31-2023