In the cutting-edge technology field of 3D printing, integrated stepper motors are gradually becoming an important force in promoting the development of the industry with their excellent performance and wide range of applications. This article will deeply explore the unique value of the integrated stepper motor in the field of 3D printing from three aspects: its advantages, its specific application in 3D printers, and the changes it brings to the industry.

1. The unique advantages of integrated stepper motors

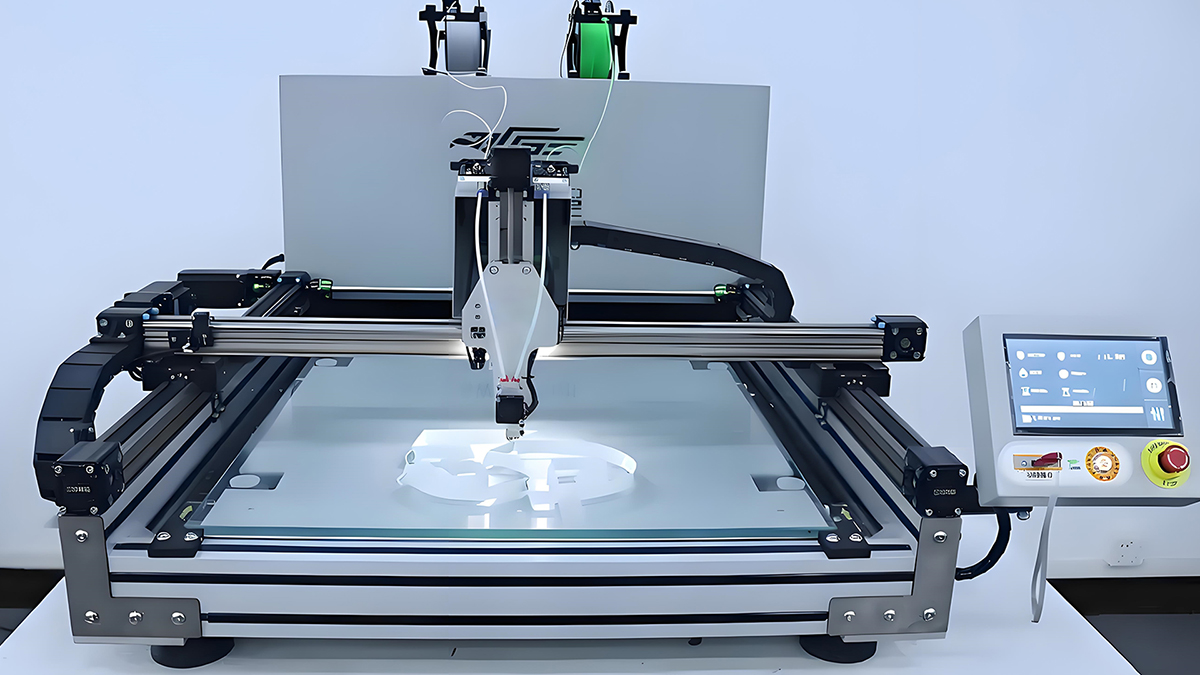

Integrated stepper motor, as the name suggests, is an innovative product that highly integrates stepper motor and driver. This design not only greatly simplifies the complexity of the system, but also significantly improves the efficiency and reliability of the motor. Compared with traditional stepper motors, integrated stepper motors have significant advantages such as compact structure, high power density, fast response speed, and high control accuracy. At the same time, it supports a variety of communication protocols, such as CANopen, Modbus, etc., making integration with 3D printer control systems more convenient and efficient.

2. Specific applications in 3D printers

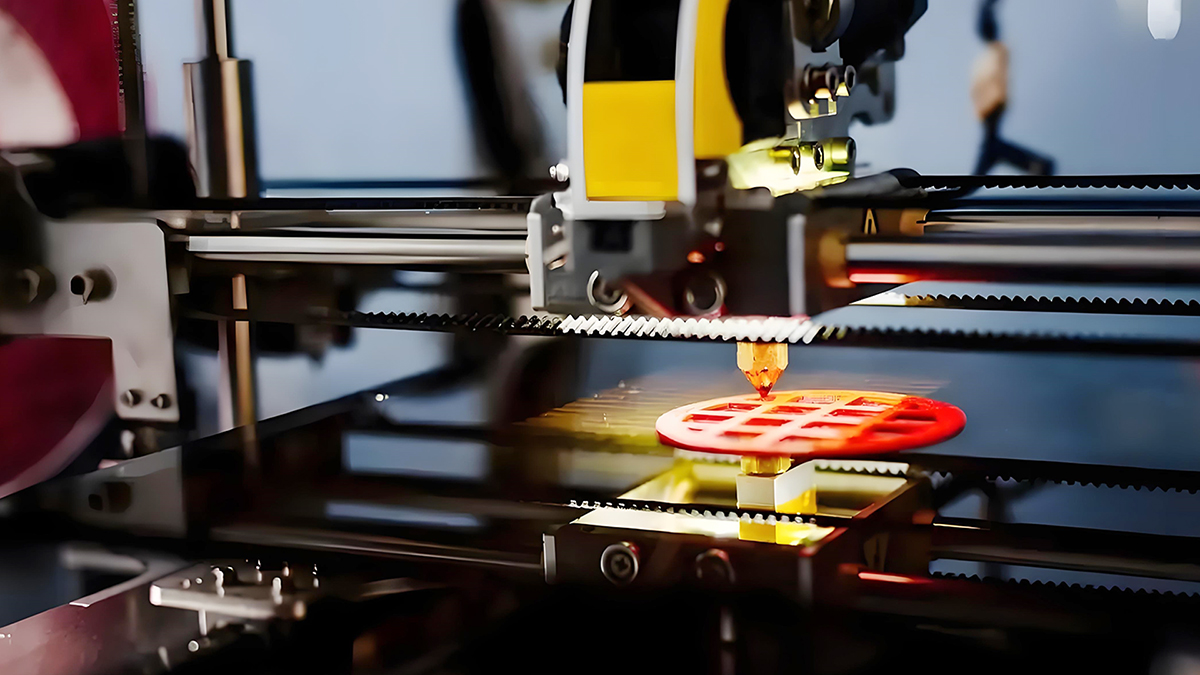

In the 3D printing process, precise control of the position and movement direction of the print head is the key to ensuring print quality. Integrated stepper motors have become an indispensable component in 3D printers due to their excellent precision and controllability. Specifically, the application of integrated stepper motors in 3D printers is mainly reflected in the following aspects:

A. Print head position control: By accurately controlling the number and frequency of electrical pulses, the integrated stepper motor can fine-tune the print head position to ensure the accuracy and uniformity of each layer of printing. Whether it is complex geometric structures or fine texture details, they can be accurately restored.

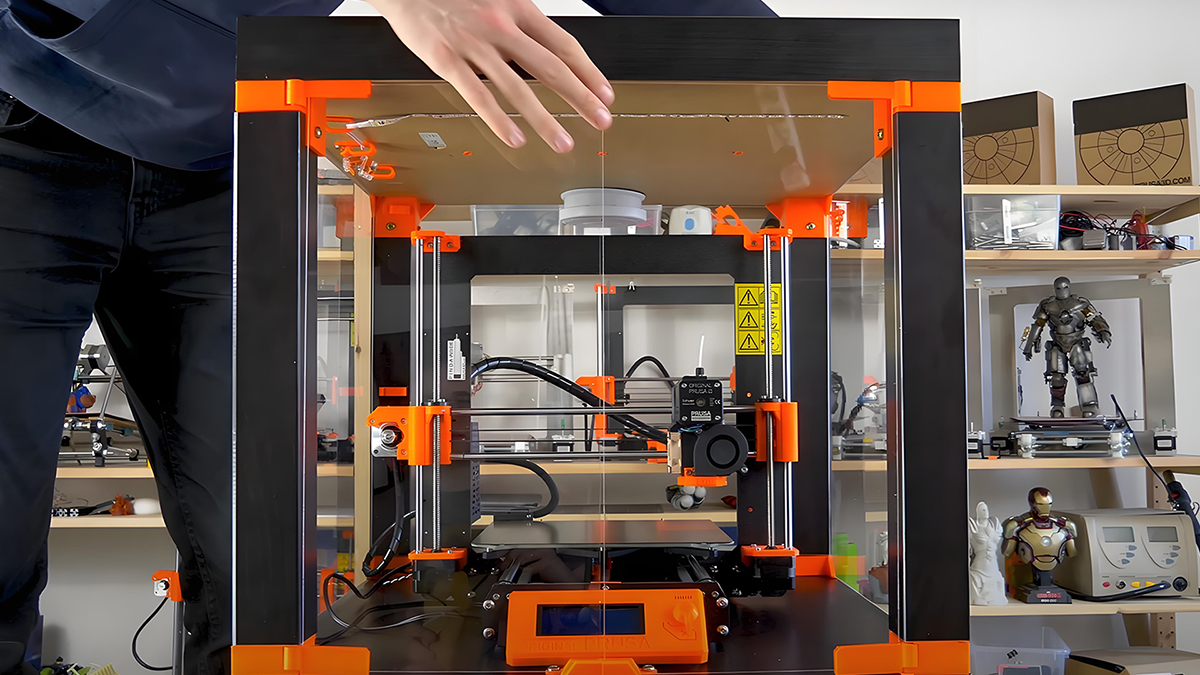

B. Printing platform lifting control: During the 3D printing process, the printing platform needs to rise layer by layer according to the preset height so that materials can be stacked layer by layer to form a three-dimensional entity. The integrated stepper motor ensures perfect connection between different levels with its high-precision lifting control, avoiding the occurrence of misalignment and defects between layers.

C. System stability and efficiency improvement: The efficient operation and stable performance of the integrated stepper motor effectively improve the overall work efficiency and printing quality of the 3D printer. At the same time, its built-in multiple safety protection functions and fault self-checking mechanisms ensure the stability and reliability of the equipment during long-term operation.

In short, as an important part of 3D printing technology, integrated stepper motors are leading the rapid development of the 3D printing industry with their excellent performance and wide application prospects. We have reason to believe that in the future, with the continuous advancement of technology and the continuous expansion of application fields, integrated stepper motors will play a more important role in the field of 3D printing and create a better life experience for us.

The market’s demand for integrated stepper motors is getting higher and higher. In pursuit of smaller size, higher integration process, and more functions, integrated stepper motors are undoubtedly the unique priority solution for equipment manufacturers. Shenzhen Zhongling Technology Co., Ltd. has been committed to the research and implementation of motion control, and actively responds to and solves the efforts of the new era for higher integration requirements. Provide customers with solutions with excellent quality and lower prices.

Post time: Aug-13-2024