n-Wheel Motor, as a highly integrated drive technology, has attracted much attention not only in the field of electric vehicles in recent years, but also has gradually become an important technical support in the field of Embodied AI because of its compact structure and high efficiency. Embodied intelligence emphasizes that agents realize perception, decision-making and execution through the interaction between physical body and environment. Its carriers, such as humanoid robots, intelligent logistics vehicles and mobile service equipment, all put forward higher requirements for the flexibility, lightweight and control accuracy of the drive system. The combination of hub motor and embodied intelligence is promoting the wide application of intelligent robots from laboratory to industrial and consumer scenes.

First, the technical characteristics and advantages of in-wheel motor

Hub motor highly integrates the drive system, transmission device and braking system into the wheel, and has the following core advantages:

1. High space efficiency: traditional transmission shaft, differential and other components are omitted, and chassis space is released, which is convenient for equipment structure optimization.

2. Independent control capability: each wheel can be driven independently, which supports accurate torque vector distribution and improves movement flexibility and stability.

3. High-efficiency output: The permanent magnet synchronous motor technology can achieve more than 93% energy conversion efficiency, and the low-speed and high-torque characteristics are suitable for dynamic response in complex terrain.

4. Modular design: it is easy to adapt to different forms of intelligent carriers, such as quadruped robots, humanoid robots or self-driving vehicles.

Second, Typical application scenarios of in-wheel motor in body intelligence

1. Joint drive of humanoid robot

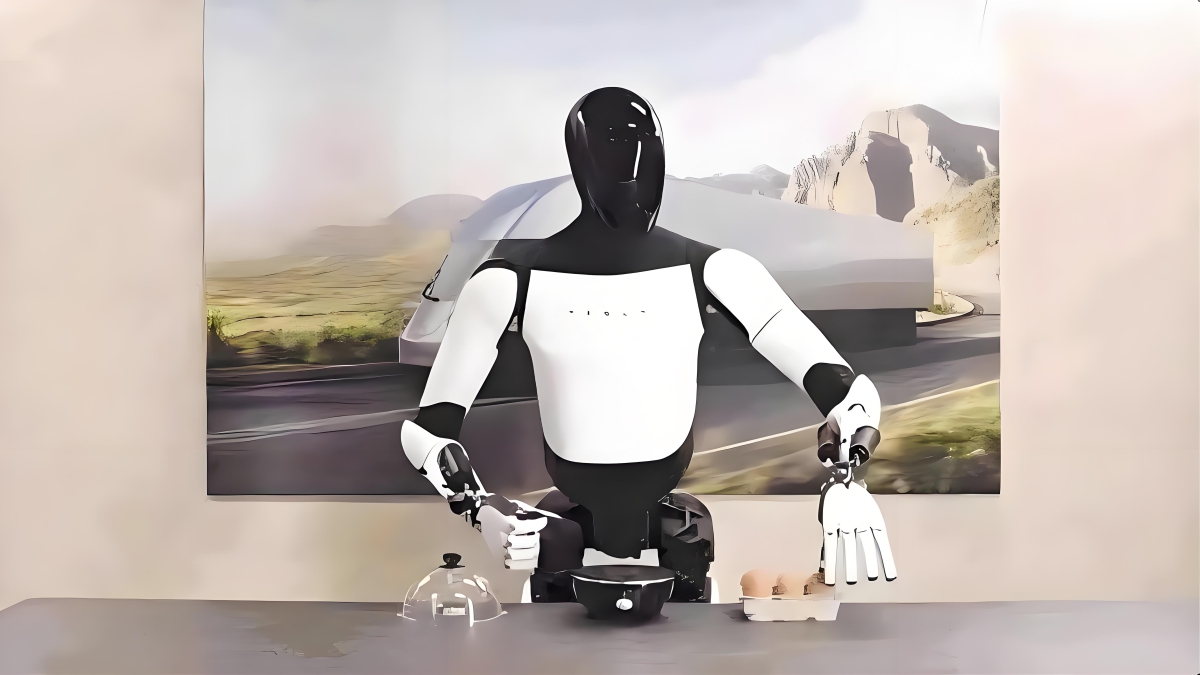

Intelligent carriers such as humanoid robots need highly flexible joint movements. The modular design of in-wheel motor can be integrated into the joints of robot feet or hands to provide precise torque control. For example, Tesla Optimus humanoid robot draws lessons from automobile driving technology, and its joint actuator adopts high-density motor design, which supports fast response and multi-degree-of-freedom movement. The dexterous hand module launched by sagitar Juchuang, a domestic enterprise, has realized the fine operation similar to human fingers (such as grasping eggs) through hub motor technology, showing its potential in the field of tactile feedback and force control.

2. Intelligent mobile platform

In the scenes of warehousing, logistics, industrial inspection, etc., intelligent equipment with body (such as AMR autonomous mobile robot) relies on the independent driving ability of hub motor to realize complex actions such as 360-degree rotation and lateral movement. Modern Mobius MobiOn concept car realizes omni-directional movement through hub motor, which provides a solution for narrow passage and accurate parking in logistics scene.

3. Special environmental adaptability

The high sealing performance and impact resistance of in-wheel motor (such as gravel resistance and roadside collision resistance verified by the Impact Test Method of Angle Module of in-wheel motor) make it suitable for emergency rescue, outdoor exploration and other unstructured environments. For example, TRON 1, a biped robot with step-by-step power, can walk stably in complex terrain such as gravel roads and stairs by driving joints through hub motors.

Third, technical challenges and innovation direction

Although the hub motor shows great potential in body intelligence, it still needs to overcome the following challenges:

1. Heat dissipation and lightweight: Long-term operation of high-power density motors is easy to lead to overheating, so it is necessary to combine new cooling technologies (such as liquid cooling or phase change materials) and lightweight alloy materials for optimal design.

2. Complexity of control algorithm: Multi-motor cooperative control needs to combine reinforcement learning and end-to-end model to improve the response speed in dynamic environment. For example, Tucki Iron robot realized 720-degree environmental awareness and real-time path planning through AI Hawkeye Vision System and end-to-end large model.

3. Cost and standardization: There is a high demand for customization of parts in robot scenes, and it is necessary to promote the standardized production of motor modules. The series of standards “Key Test Methods for Angle Modules of Automotive Hub Motors” issued by China provide a reference for technical compatibility and reliability evaluation.

Fourth, the future trend: cross-border integration and ecological construction

1. Technology reuse and supply chain collaboration

Mature technologies in the automobile industry chain (such as laser radar and high-density motor) are accelerating the migration to embodied intelligence. For example, sagitar Juchuang adapts vehicle-mounted lidar to robot environment modeling, while hub motor manufacturers can reuse automotive powertrain technology to develop joint drive modules.

2. Intelligent integration

Combined with multi-modal large model (such as vision-language-action fusion model), the intelligent device with body driven by hub motor can improve the task generalization ability. For example, Google DeepMind’s RT series model optimizes the dynamic control strategy of in-wheel motor through virtual environment training.

3. Application scenario expansion

Extending from industrial manufacturing to home service, in-wheel motors will support the popularization of consumer products such as domestic robots and elderly care equipment, and further release human demand.

Shenzhen Zhongling Technology Co., Ltd. has been exploring for making the most stable motion control products. Zhongling Technology mainly produces robot hub servo motor driver, digital stepping driver motor, closed-loop stepping system, digital DC servo system, integrated servo drive motor, multi-axis motion controller and special equipment, such as security equipment attendance, access control, servo sensing quick-pass door and other products in artificial intelligence robots, Industrial control, electronic machinery control, measurement, laser, medical treatment and other equipment are widely used in hundreds of automation industries. At present, our products have been exported to Southeast Asia, Europe and America and other countries and regions, showing the accumulated achievements in the field of machine automation in China. I believe that Zhongling Technology will definitely contribute to the artificial intelligence robot industry in the future and work together.

Post time: Mar-11-2025